Product Information

Chemical Name:γ-(METHACRYL OXYL)PROPYL TRI METHOXY SILANE

Product Code:LT-570

Molecular Formula:C10H20O5Si

Molecular Weight:248.4

CAS NO.:2530-85-0

Properties and Reactivity

◆ LT-570 It is a reactive chemical with methacrylate-based organic functional groups and trimethoxy-silicon-based inorganic functional groups. This bifocal structure gives LT-570 special properties: it is able to bond inorganic materials (such as glass, silica) and organic thermosetting resins together to promote adhesion, crosslinking agents and/or surface modifiers.

◆ It is a colorless transparent liquid with sensitive to light and heat, with a distinct sweet odor, soluble alcohols, aliphatic or aromatic hydrocarbons.

◆ In the presence of water (and a suitable catalyst such as acetic acid), LT-570's alkoxy groups will hydrolyze to form methanol and active silanol groups, forming bonds on various inorganic substrates. Methacryloxy can react with suitable polymers.

◆ Suitable inorganic materials such as: glass, glass fiber, glass wool, mineral wool, silica, quartz, sand, quartzite and mica; As well as aluminum hydroxide, kaolin, talc and other silicate fillers, metals and metal oxides.

◆ Suitable resins for treatment include unsaturated polyester, acrylic and vinyl resins.

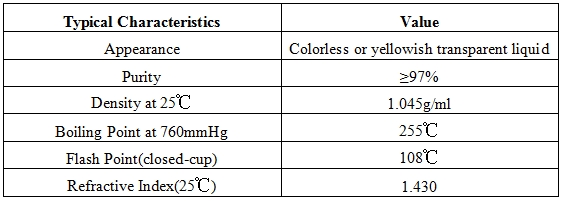

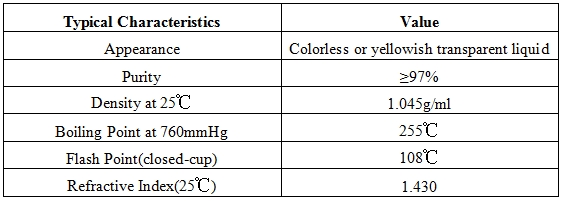

Technical Data

Note: the above data is for reference only, cannot be as a technical specification.

Application

LT-570 is used as a bonding accelerator in many applications, such as:

◆ Components of glass fiber infiltrators (glass fiber fillers used to fill unsaturated polyester resins and polyolefin).

◆ Finishing agent for glass fibers filled with unsaturated resins.

◆ Surface modifiers for pigments and fillers of hot solids (unsaturated polyester resins, MMA), thermoplastics (polyester and polyolefin) and elastomers.

◆ As an additive to peroxide-induced crosslinking of packed elastomers.

◆ As an additive to casting resins (unsaturated polyester, MMA).

LT-570 can pretreat inorganic substrates by dipping, spraying or coating. It can also be added directly to the resin system (adding process). As a pretreatment, silane can:

◆ Add directly.

◆ Pre-dissolved in organic solvent.

◆ Dissolves in a mixture of organic solvents and water to achieve partial hydrolysis.

◆ When fully hydrolyzed in an aqueous solution to prepare an aqueous pretreatment solution, LT-570 should be dissolved in water in 1-5wt.- % and PH adjusted to 3-4 with acetic acid. When the silane is completely hydrolyzed, if the solution becomes cloudy again, it can no longer be used. In the addition process, LT-570 can be mixed with resin or polymer beforehand or added simultaneously with filler. The prerequisite for this method is the compatibility between silane and the corresponding resin, so that silane must not react with the resin in advance.

The correct use of LT-570 can achieve the following effects in unsaturated polyester resin systems with high filler loads:

◆ Improve dispersion of pigments/fillers.

◆ Reduces pigment/filler deposition.

◆ Reduces viscosity and improves resin fluidity.

◆ Improve the mechanical properties of mold products.

◆ Improve the mold product resistance to boiling water, acid and alkali.

LT-570 can also be used as a monomer in synthetic resins (e.g., emulsion dispersion polymerization) to partially replace the monomer oxidized by methylacrylyl (generally 0.5-3%, but sometimes up to 20%). The introduction of silane into resin products can lead to a number of performance improvements in the final application:

◆ wet bond strength.

◆ Resistant to chemical corrosion.

◆ Scratches resistance.

鄂公网安备 42900402000406号

鄂公网安备 42900402000406号 Home

Home Tel

Tel Product

Product